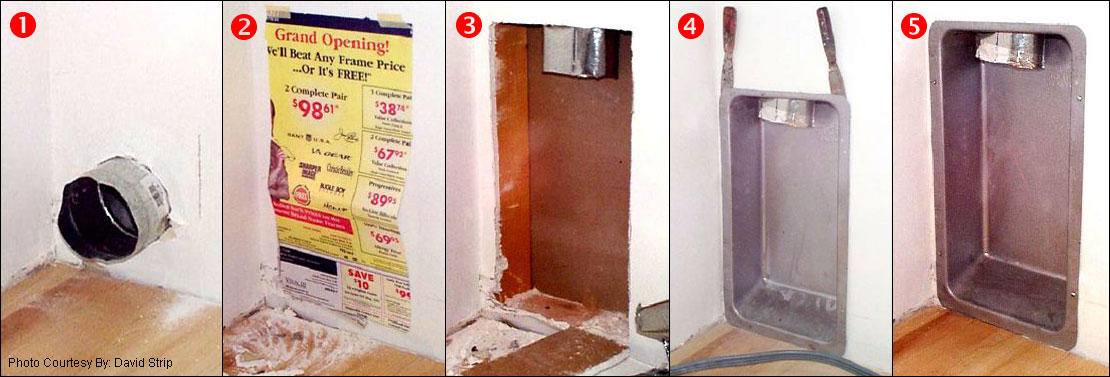

THE DRYERBOX REFIT --- "As you can see, the installation is way down in a corner, where I recently moved the vent prior to rediscovering mention of your product in Fine Homebuilding. You do not include a template, so I made one from an ad in the Sunday paper. A template would be a nice addition, since it would be truly the right size with no guesswork, and could include the correct locations for screw holes.

I included a picture showing the box with small putty knives in the corners. These were a great help. Before I used them, the upper edge would dig into the sheetrock and hang-up. When I ordered, you warned this was not an easy installation. Boy were you ever right. I might go one step farther and list the product as intended for professional installers only. I think I'm quite a bit more sophisticated about these things than most homeowners but this still was a pain. The hardest part was cutting the existing snaplock pipe. There's just no place to get any kind of tool in there. I think it might have been easier to just rip out enough sheetrock to use the new construction model. For a professional renovator/remodeler, once you've done this you learn a bunch of tricks that make it reasonable the next time around, so I don't see any reason to discontinue the product.

One more thing. It may have been in the instructions and I missed it, but don't do like I did and install it flush to the floor. It just makes a hard job that much worse. Of course, by the time I figured it out, I was done. For retrofits, you might consider a two part box - basically saw the one you have in half. If you don't want to offer it that way, you might at least suggest it as a solution to really difficult installations.

Also, if you know a way to cut that damn pipe in the wall, I'd still like to hear it. Your photo shows a hacksaw, but I don't see how you can cut more than about a third of the pipe. If I were doing a retrofit again and didn't want to rip out the sheetrock, I'd give pretty serious thought to just cutting through the sheetrock on the far side of the installation, using a reciprocating saw, slicing through the pipe in the process. (In fact, I might mark a pilot hole, and do the cut from the back, since it would provide support for the saw. Repairing the simple cut in sheetrock would be a picnic compared to trying to cut the pipe from the front. Anyway, we LOVE the product. Our dryer now fits comfortably in the closet designed in 1972 to hold a smaller dryer."

By David Strip in Albuquerque, New Mexico